Product Description

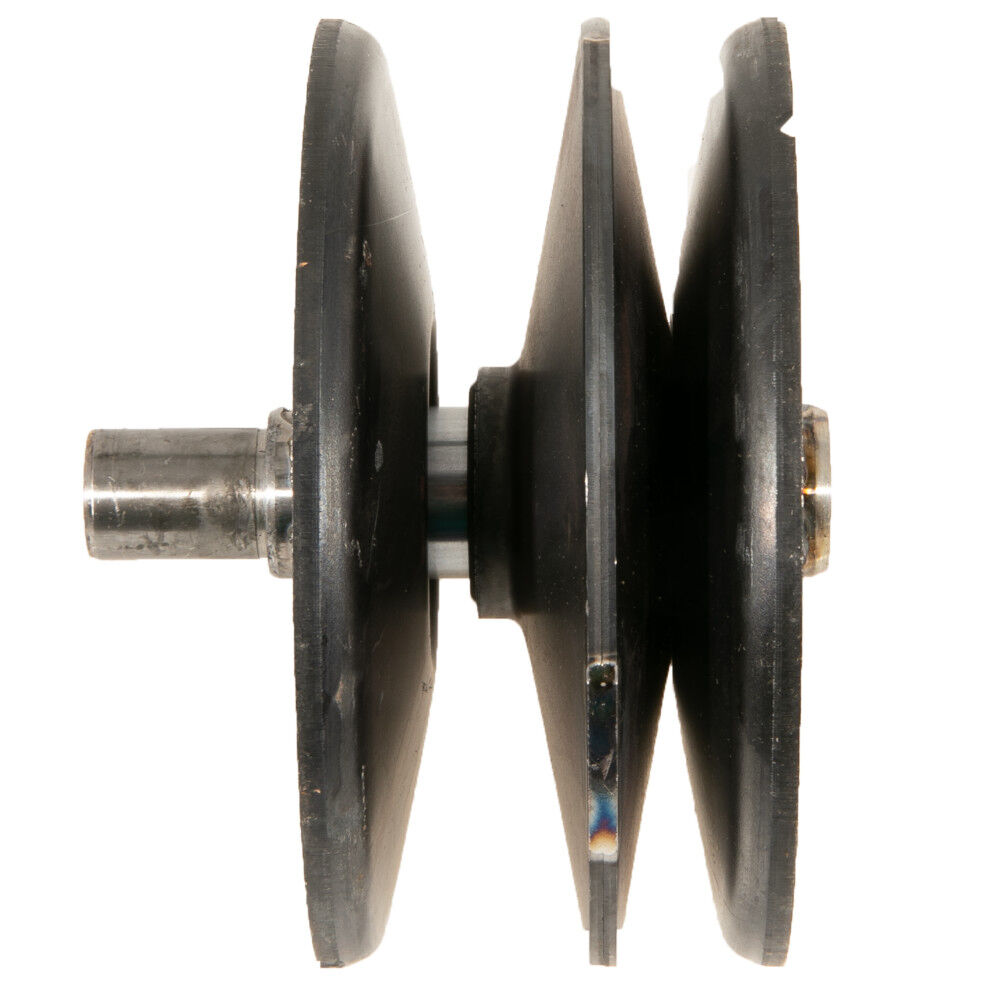

Competitive Price Heavy Duty Gravity Roller SS304 Light Steel Idler Pulley

Product Description

Idler rollers, or sometimes simply known as conveyor rollers, are cylindrical-shaped bars that run along and underneath a conveyor belt. There are many different types of idler rollers with varying functions.

Usually, idler rollers aid in the supporting of weight and impact of the materials being transported along the belt. They also assist in the smooth, continuous movement of the material along the belt.

Idler rollers can be self-aligning and assist in maintaining the belt tracking. Depending on the structure and shape of the conveyor belt, the rollers are usually positioned within a metal frame and are known as idler sets.

Detailed Photos

Product Parameters

| Diameter | 60-219mm |

| Length | 100-3500mm |

| Tube | Q235(GB) |

| Shaft | 45# steel(GB) equal to C45 |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RZ&2Z wigh C3 clearance |

| Grease | Lithium soap type grease,grease retaining inner seal with Multi-stage Labyrinth and Retention Cap with Outboard Rubbing Flinger Seal |

| Lubrication | Grease is Lithium soap type grease with Rust Inhibitors |

| Welding | Mixed gas shielded arc welding end |

|

Painting |

Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

|

D(mm) |

L(mm) |

Bearing model |

|

89 |

180,190,200,235,240,250,275,280,305,215,350,375,380,455,465,600,750,950,1150 |

204 |

|

108 |

190,200,240,250,305,315,360,375,380,455,465,525,530,600,700,750,790,800,950,1150,1400,1600 |

|

|

133 |

305,375,380,455,465,525,530,600,700,750,790,800,900,950,1000,1100,1150,1400,1600,1800,2000,2200 |

|

|

159 |

375,380,455,465,525,530,600,700,750,790,800,900,1000,1050,1100,1120,1150,1250,1400,1500,1600,1700,1800,2000,2200,2500,2800,3000,3150 |

|

|

193.7 |

2200,2500,2800,3000,3150,3350 |

308 310 |

|

217 |

600,640,1050,1120,1600,1700,3150,3350 |

308 310 |

Certifications

Packaging & Shipping

Company Profile

ZheJiang CHINAMFG Rubber Products Co., Ltd is a leading professional manufacturer of conveyor belts & conveyor accessories in China. The main workshops cover 20,000 square CHINAMFG in the total 60,000 square CHINAMFG of the plant. The applied technology and equipment in the advanced production lines are state of the art in the industry. The sales headquarters is located in the capital of China, ZheJiang with branches in domestic and abroad.

It specializes in following 3 series: 1) Heavy-duty Conveyor Belt, including universal EP/NN and CC Belt, Chevron Belt, Oil Resistant Belt, Abrasion Resistant Belt, Heat Resistant Belt, Fire Resistant Belt, Chemical Resistant Belt, Sidewall Belt, Flat Transmission Belts, 2) Rubber Sheets, including SBR, NBR, NR, CR, EDPM, Rubber With Insertion 3) Conveyor accessories. These 3 series of products conform to RMA, DIN, ASTM and ISO specifications.

Its products, honored with “The most Advanced level of Products” by the Committee of Science and Technology, have been widely used in mining and quarrying, power stations, steel plants, bulk cargo terminals, cement industry, and other material handling fields. With great success in domestic market, it has been focusing on global market with several hundreds of foreign valued customers in Asia, South America, North America, Africa and Europe.

The company mission:

1.Supply one-stop outstanding service to global customers.

2. Engage in complete solutions with conveyor belting and power transmission belting.

3. Persist in technology improvement and quality control in the whole process of production and service.

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Parallel Conveyor Idler |

| Dimension(L*W*H): | Variable |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

How do variable pulleys contribute to energy efficiency in industrial processes?

Variable pulleys play a significant role in enhancing energy efficiency in industrial processes. By providing precise control over speed and load adaptation, variable pulleys offer several benefits that contribute to reducing energy consumption and optimizing overall efficiency. Here are some ways in which variable pulleys contribute to energy efficiency:

- Optimized power transmission: Variable pulleys efficiently transmit power from the input shaft to the output shaft, minimizing energy losses. By adjusting the position of the pulley’s movable flanges, the effective diameter of the pulley changes, allowing for optimal power transmission based on the load requirements. This efficient power transmission reduces energy waste and ensures that the machinery operates at its optimum power efficiency.

- Speed control: One of the primary advantages of variable pulleys is their ability to control the speed of machinery. By adjusting the pulley’s effective diameter and changing the speed ratio between the input and output shafts, operators can match the speed of the machinery to the specific requirements of the process. This prevents over-speeding or under-speeding of the equipment, resulting in energy savings by avoiding unnecessary power consumption.

- Load adaptation: Variable pulleys allow machinery to adapt to varying load conditions. By adjusting the pulley’s setting, operators can vary the torque and speed output of the system to match the requirements of the load. This load adaptation ensures that the machinery operates at the most efficient operating point, minimizing energy waste and improving overall energy efficiency.

- Efficient process control: Variable pulleys enable precise adjustments in speed and torque, providing better control over industrial processes. This control allows operators to optimize the process parameters based on energy efficiency considerations. For example, in applications where a slower speed can achieve the desired outcome, operators can adjust the pulley settings accordingly, reducing energy consumption while maintaining process effectiveness.

- Reduced mechanical losses: Variable pulleys help minimize mechanical losses in industrial processes. By avoiding fixed-speed operation and using variable speed control, the machinery can avoid unnecessary friction and wear associated with running at higher speeds than required. This reduction in mechanical losses contributes to energy efficiency and can extend the lifespan of the equipment.

- Energy recovery: In certain industrial processes, variable pulleys can enable energy recovery systems. For example, in applications where the machinery produces excess energy during certain phases, variable pulleys can be adjusted to recover and utilize that energy elsewhere in the process. By capturing and reusing this energy, overall energy consumption can be reduced, leading to improved energy efficiency.

The precise control and load adaptation capabilities of variable pulleys make them valuable tools in optimizing energy efficiency in industrial processes. By reducing energy waste, enhancing process control, and minimizing mechanical losses, variable pulleys contribute to significant energy savings and promote sustainable industrial operations.

Can variable pulleys be used in both industrial and DIY applications?

Yes, variable pulleys can be utilized in both industrial and DIY (Do-It-Yourself) applications. The versatility and adjustability of variable pulleys make them suitable for a wide range of uses, from large-scale industrial machinery to smaller DIY projects. Here’s a closer look at how variable pulleys are applicable in both contexts:

Industrial Applications:

In industrial settings, variable pulleys are commonly employed in various types of machinery and equipment for speed control and power transmission. Some notable industrial applications of variable pulleys include:

- Conveyor Systems: Variable pulleys are used in conveyor systems to adjust the speed of the conveyor belts, allowing for efficient material handling and sorting processes.

- HVAC Systems: Variable pulleys can be found in heating, ventilation, and air conditioning (HVAC) systems to regulate fan speeds and control airflow, optimizing energy efficiency and comfort.

- Machine Tools: Variable pulleys are utilized in machine tools such as lathes, milling machines, and drill presses, enabling operators to adjust the rotational speed for different machining operations.

- Automotive Industry: Variable pulleys are employed in automotive applications, such as continuously variable transmissions (CVT), where they allow for seamless speed adjustments and improved fuel efficiency.

- Industrial Mixers and Agitators: Variable pulleys are used in mixers and agitators to control the rotational speed of blades or paddles, ensuring proper mixing and blending of materials.

DIY Applications:

In DIY applications, variable pulleys can be utilized by hobbyists, enthusiasts, and individuals working on personal projects. Some common DIY applications of variable pulleys include:

- Power Tools: DIY enthusiasts often incorporate variable pulleys into homemade power tools, such as belt sanders, drill presses, and grinders, to achieve adjustable speed control.

- Garden and Yard Equipment: Variable pulleys can be used in DIY projects involving garden and yard equipment, such as lawnmowers or leaf blowers, to adjust the speed of the cutting blades or the airflow.

- Small Machinery: Variable pulleys can be applied in DIY projects involving small machinery, such as mini lathes or mini milling machines, allowing users to customize the rotational speed for specific tasks.

- Experimental Setups: Variable pulleys can be incorporated into DIY experimental setups or scientific projects where adjustable speed control is required, such as in physics experiments or mechanical demonstrations.

The adaptability of variable pulleys makes them suitable for a wide range of applications, both in industrial and DIY contexts. Whether it’s for large-scale industrial machinery or small-scale personal projects, variable pulleys provide a flexible and efficient means of achieving adjustable speed control and power transmission.

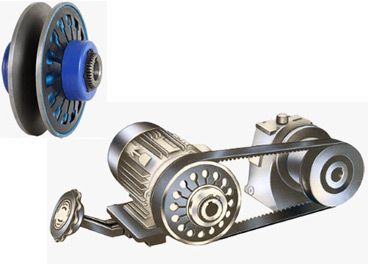

What is a variable pulley, and how does it function in mechanical systems?

A variable pulley, also known as a variable speed pulley or a variable drive pulley, is a type of pulley designed to provide variable speed ratios in mechanical systems. It consists of two or more pulley halves that can move relative to each other, allowing for adjustment of the effective diameter and thus changing the speed ratio between the input and output shafts.

The primary function of a variable pulley is to provide a means of continuously adjusting the speed of driven components in a mechanical system without the need for manual gear changes or transmission adjustments. This flexibility is particularly useful in applications where speed variations are required to accommodate different load conditions or to achieve specific operational requirements.

The operation of a variable pulley is based on the principle of changing the effective diameter that the belt or chain engages with. It typically consists of a fixed pulley half and a movable pulley half, both connected by a belt or chain. The movable pulley half is designed to slide or pivot, which changes the distance between the pulley halves, thus altering the effective diameter.

When the movable pulley half is positioned closer to the fixed pulley half, the effective diameter increases. This results in a larger belt or chain contact area and a higher speed ratio between the input and output shafts. Conversely, when the movable pulley half is positioned farther away, the effective diameter decreases, leading to a smaller contact area and a lower speed ratio.

Variable pulleys can be actuated by different mechanisms, such as hydraulic, pneumatic, or mechanical means. The actuation mechanism allows for precise adjustment of the movable pulley position, enabling smooth speed transitions and accurate control.

One common application of variable pulleys is in automotive vehicles, where they are used in continuously variable transmissions (CVTs). In a CVT, the variable pulleys provide seamless speed adjustments, allowing the engine to operate at its optimal speed for different driving conditions, resulting in improved fuel efficiency and performance.

In summary, a variable pulley is a pulley system that enables continuous adjustment of speed ratios in mechanical systems. By changing the effective diameter through the movement of pulley halves, it allows for variable speed control without the need for manual gear changes. Variable pulleys find applications in various industries, providing flexibility, efficiency, and precise speed control in mechanical systems.

editor by CX

2024-05-17